The growing global community of 3D printing is, in large part, an online discussion. Printmakers and designers around the world share tips and tricks, open source designs, and free advice on various online forums. All3DP publishes a list every month of the 50 coolest things to 3D print. This month, it includes survival whistles, sound amplifiers, and wrenches. Printing these, as well as pretty much any other object you can think of, is something that Virginia’s first and only 3D print shop, 3D Central, specializes in.

Located in Scott’s Addition, 3D Central is a one-stop shop for where the future of the sector is moving. It allows for in-person consultations, assistance, and a physical space for 3D printing.

Co-founder Chris Caswell started the store as an Etsy shop in 2011 with his brother, Jonathan, and his wife, Cyndi. “We started the business together when we moved down to Richmond from Boston,” said Chris. As the number of printers and customers grew, they were able to open their own store.

The storefront functions more as a workshop than a retail space. Plastic bits litter the surfaces, designs sit beside their physical manifestations, and everywhere you turn is a new small part of a bigger thing. The bits of plastic scattered about are a result of post-print perfection. “The print isn’t done as soon as it comes out,” said Jonathan.

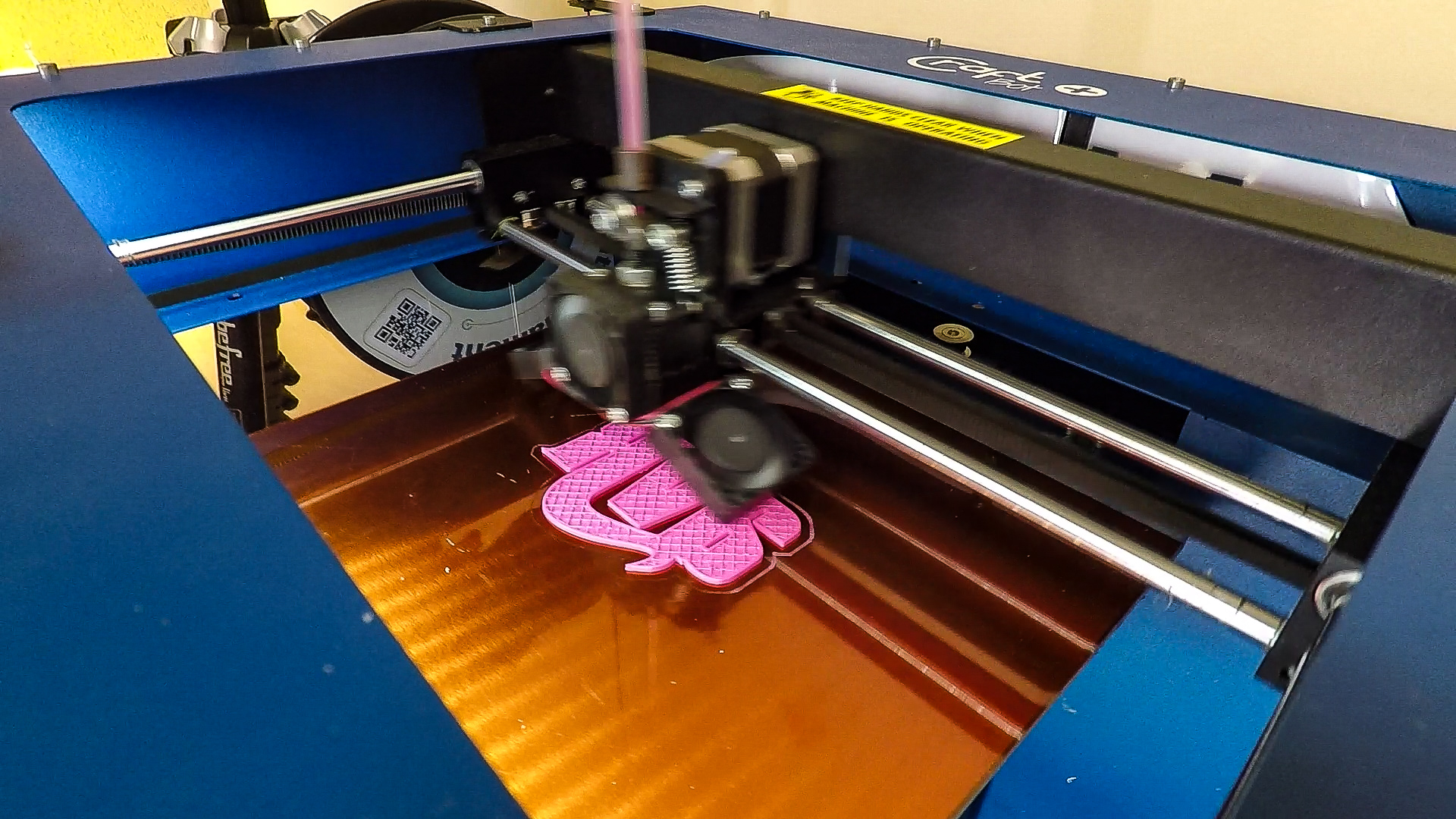

3D Printed Logos. Photo by Christina McBride

During a printing session for RVA Magazine logos, he explained the process through each stage. Computer-aided design (CAD) software is used to model all 3D objects. The precision specifications for printing are laid out in the CAD design: the size, shape, and detail. After the design is created, it is converted into a file format used for 3D printing and rapid prototyping, which takes into account the surfaces of the design.

“Everything, everything, is laid out in the software,” said Chris.

That file then has to be sliced into layers so the printer can build the model from the bottom up. Since every object is made up of plastic layers, the more layers they use, the more detailed the print becomes.

“Then you drag the design to your flash drive and stick it in the printer,” said Jonathan.

Spools of thick ABS or PLA plastic thread are looped into the machine, determining the type and color of plastic the print will bring to life. Different types of plastic (or sometimes, rubber) work best with different designs. For instance, one customer needed to print a specific screw for his sailboat that he couldn’t find anywhere else. Another asked for custom cookie cutters for her pre-made gingerbread house sets. Another needed to print the prototype for a business model.

The Caswells were most excited about a personal printing accomplishment. In one design, they were able to create an accordion-like hinged extension that fans out to almost as wide as Jonathan’s wingspan. It’s the “extendo” in the extendo arm. Like most of their prints, it’s a part, but they haven’t yet attached it to anything.

Jonathan smiled and let it stretch out to his side, saying, “It could be a giant grab-arm.”

As the technology continues to grow, more opportunities for both commercial and personal use have become available. According to CAD Crowd, MIT has recently developed a 3D printer that outputs almost 10 times faster than the commercial printers currently available — which is leading to breakthroughs in medicine, engineering, and event printed metals.

3D Central taps into these trajectories. In the shop, one could easily spy trade show models, spare technology parts, figurines, custom plastic busts, the Millennium Falcon, and even a shoe. However, one of their more popular products is their Yuni: Single-Sided Stereo Headphone for listeners with hearing problems. The product is 3D printed, assembled, and wired by 3D Central in-house.

Plastic Spools for Printing. Photo by Christina McBride

The world of 3D printing is not without controversy, however. When asked about his stance on printing guns, Chris said, “Certainly we don’t do that. But just like other people have hobbies, some gun owners think of it as a hobby, and need parts for that sort of thing.”

He said that, besides plastic being a bad material for weapons, for the price of a printer (the cheapest, fully assembled model runs about $600) and the time putting the gun together, one might as well spend the money on a real gun.

The debate on 3D printed guns is complicated. Printed guns do not have serial numbers like weapons you’d buy in a store, so they fall under the category of “ghost guns,” which are not legal to buy or sell. What’s more, under the stipulations set forward by the Undetectable Firearms Act, guns have to have metal parts, regardless of whether those parts are necessary for the production, so that they’ll show up in metal detectors. And it is not just a Second Amendment issue: these guns are designed and printed by people, which brings free speech into the debate.

Nonetheless, the only weapons 3D Central prints are for cosplay. A pile of printed Nerf guns and accessories hang out in a corner, along with a Nerf dart shooter; they are bright, bulky, printed, and assembled in-house. The most awesome part: there’s also a sword.

A few years ago, this technology seemed esoteric and out of reach. Now public schools, libraries, and universities all have 3D printers available for use. Communities at large and private owners will benefit from 3D printing technology – designs and prints can be finished before an Amazon package would reach your door. Even NASA can now send designs for otherwise-expensive spare parts to be printed at the International Space Station for in-space construction. Universities are also testing the bio-printing of viable 3D cells to end the organ transplant shortage. The future of the technology seems limitless.

Right now, though, its real merit is in providing quick, simple solutions — like printing a new phone case, or a Halloween costume prop. The technology is popular with tinkerers and craftspeople, and many of these owners have online businesses for 3D printed gifts or toys, some of which are now popping up on Etsy and Amazon.

But despite 3D printing’s increased accessibility, it’s still not an appliance, according to Jonathan. With no simple means to create objects, like pushing a button on a microwave, he likened having a 3D printer at home to owning a woodworking machine. To output a finished product, it requires knowledge of the software and the ability to design each object, as well as time, effort, and a willingness to try again if the first print fails. Unless consumers put serious time into in the 3D printing technology, as artists like Chris and Jonathan have done, it is unlikely that the current technology will be used to its full potential.

To learn more about the 3D printing process, you can find Chris and Jonathan on their website and Instagram, and check out their products on Etsy and Amazon.